Preventing Incidents and Injuries: The Role of

Unsafe Acts,

Unsafe Conditions, and Near Misses

Preventing

Incidents and Injuries: The Role of Unsafe Acts, Unsafe Conditions, and Near

Misses

Unsafe

Acts, Unsafe Conditions, and Near Misses: Understanding the Importance of

Workplace Safety

Workplace

safety is a crucial aspect of any industry, and it is important for employers

and employees to understand the importance of identifying and mitigating unsafe

conditions and unsafe acts. This not only helps to prevent accidents and

injuries, but it also helps to increase productivity and reduce costs associated

with accidents. This will also helps for ensuring the safer workplace that

resulting a safe return of employees.

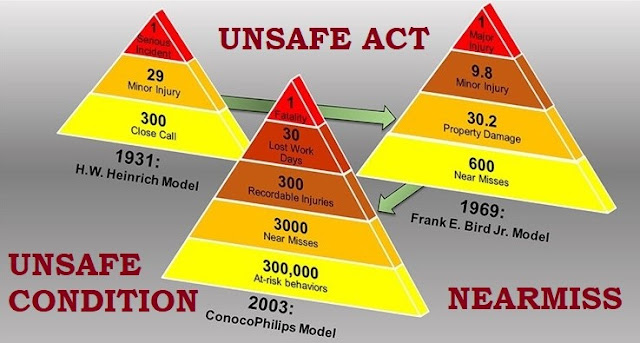

Unsafe

Acts are done the employees, its defined as any intentional or unintentional

actions that violate safety procedures, policies, and regulations. Examples of

unsafe acts include horseplay, not wearing personal protective equipment,

disregarding warning signs, and improper use of equipment or using the damaged tools/equipment.

Unsafe

Conditions, on the other hand, are environmental factors that pose a threat to

the health and safety of employees. These include floor opening, missing

machine guarding, poor ventilation, and wet floors, to name a few.

Both

unsafe acts and unsafe conditions can lead to serious accidents and injuries,

and it is important for employers and employees to work together to identify

and correct these hazards before they result in an injury or accident. Employees

to be trained on the identification Unsafe Act and Unsafe Condition, the reward

system will motivate employees to report & rectify the same.

A

Near Miss is a close call or almost-accident that could have the potential for

the serious injury if it had not been for a stroke of luck or the quick action

of someone. All the Near Misses to be reported and to be investigated for the root

cause that will help to prevent reoccurrence such incidents. Near Misses are a

valuable tool for employers to identify and address potential hazards in the

workplace, and they can help to prevent future accidents and injuries.

SAFETY CULTURE ASSESSMENT CHECK POINTS

To

ensure workplace safety, it is important for employers to have a comprehensive

safety management program in place, which includes regular safety inspections, safety

committee meetings, top management engagement, safety training, and prompt

correction of any identified hazards. Employees also play a critical role in

maintaining a safe workplace by reporting any unsafe acts or conditions and nearmisses

they observe and following established safety procedures.

It

is also important to conduct regular safety meetings to discuss any near misses

and identify any trends or patterns. This helps to raise awareness and

encourages employees to take an active role in promoting safety in the

workplace.

In

conclusion, Unsafe Acts, Unsafe Conditions, and Near Misses are all critical

components of workplace safety for creating the safer workplace for the

employees for the safe execution of the jobs. By working together, employers

and employees can create a safe and productive work environment, reduce the

risk of accidents and injuries, and increase overall efficiency and

profitability with safety culture in place.

WELDING & CUTTING HOT WORK SAFETY

ELIMINATION OF WORKPLACE HAZARDS

"Preventing

Accidents and Injuries: The Role of Unsafe Acts, Unsafe Conditions, and Near

Misses"

"Workplace

Safety 101: Understanding Unsafe Acts, Conditions, and Near Misses"

"Creating

a Safe Work Environment: The Significance of Unsafe Acts, Conditions, and Near

Miss Incidents"

"Avoiding

Hazards in the Workplace: How to Recognize and Address Unsafe Acts, Conditions,

and Near Misses"

"Workplace

Safety Matters: The Importance of Monitoring Unsafe Acts, Conditions, and Near Miss

Incidents"

“Unsafe

Acts, Unsafe Conditions, and Near Misses: Understanding the Importance of

Workplace Safety”

Workplace

safety, unsafe acts, unsafe conditions, near misses, accidents, injuries,

productivity, costs, personal protective equipment, warning signs, equipment,

hazards, comprehensive safety program, safety inspections, safety training,

correction, regular safety meetings, awareness, promoting safety, efficiency,

profitability.

No comments:

Post a Comment