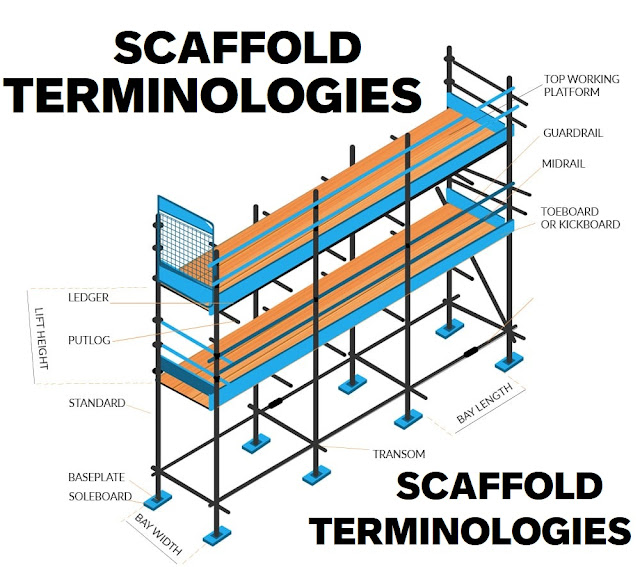

Part 2 - Scaffolding Terminologies

Scaffolding operation in any

industry is considered as highly technical operations with serious hazard

potential. Unless correct steps are taken, a loss prevention program at work

site, it may end up with serious trouble with loss in job schedule, injury to workmen,

company image and damage to property. Hence, to perform the job safely,

knowledge on scaffolding , safe erection and maintenance & inspection are

essential to the execution team.

The scaffolding is having many

types like roof scaffolding, hanging scaffold, suspended scaffolding, mobile

scaffold platform, rolling scaffold, aluminium scaffolding, mobile aluminium

scaffold, U Jack scaffolding, portable scaffold tower etc.

Scaffold Terminologies

Caster (Castor) : A pivoting wheel,

containing a wheel lock, which is attached to a vertical post (standard) of a

mobile scaffold to allow for manual movement of the scaffold.

Coupler (Fitting, Clamp) ; A

component or device used to fix scaffold tubes together.

Types of couplers include:

Adjustable (Swivel) Coupler : A

device used for connecting two tubes together at an angle other than 90 .

Bearer (Single or Putlog) Coupler :

A device used for fixing a bearer (transom or putlog) to a runner (ledger), or

to connect a tube used only as a guardrail to a post (standard).

Check (Safety) Coupler : A

Right-angle coupler added to a loaded joint on an underhung scaffold to give

supplementary security against slip to the coupler carrying the load.

End-to-End (Sleeve) Coupler : A

device used for externally joining two scaffold tubes co-axially end to end.

The steel divider is located centrally to ensure equal insertion of each tube.

Girder Coupler : A device used for

connecting a scaffold tube to a steel wide flange beam (I-beam). Girder

couplers shall only be used in pairs, one on each opposite flange.

Load Rating : Live load for

scaffold design and maximum intended loading shall be per the following

categories:

Light-duty : Scaffold designed and

constructed to carry the weight of workmen only, with no material storage other

than the weight of tools. Commonly used for inspection, painting, access and

light cleaning. Uniformly distributed maximum intended load is 120 kg/m2 (1.2

kN/m2).

Medium-duty: Scaffold designed and

constructed to carry the weight of light materials, tools and workmen.

Scaffolds used for abrasive blast cleaning (“sandblasting”) shall be classified

Medium-duty if there is potential for buildup of abrasive on the platforms (all

platforms are not continuously cleaned of abrasive). Uniformly distributed

maximum intended load is 240 kg/m2 (2.4 kN/m2).

Special-duty: Scaffold specially

designed and constructed to carry maximum intended loads greater than 240 kg/m2

(2.4 kN/m2) (50 psf), such as masonry work, piping or equipment, and is

classified as a Special Scaffold.

4 - WORK AT HEIGHT PRECAUTIONS -

No comments:

Post a Comment