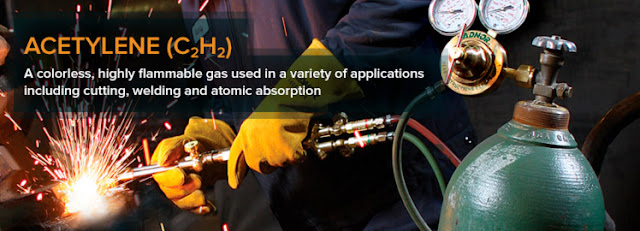

Safe Use of Acetylene Gas

UN SAFE ACT & CONDITION, NEARMISS

TOOL BOX TALK MEETING TRAINING

Safe Storage of Acetylene Gas Cylinders

Store Acetylene gas cylinders in a

safe well ventilated area that is secure and lockable, when not in use. Ensure

the storage area is kept locked. Never store acetylene gas cylinders in

occupied buildings, unventilated rooms, underground rooms (cellars) or in areas

accessible to the employees without any approval.

Store Acetylene gas cylinders away

from heat and ignition sources, flammable or corrosive materials.

Cylinders should only be stored in

areas where water cannot accumulate as this can cause corrosion to the cylinder

base.

Ensure that cylinders are secured

upright.

CHEMICAL SAFETY HAZARDS & MSDS

Ensure the storage area is designated

“NO SMOKING” and that there are no other ignition sources in the area.

Ensure MSDS is displayed in the

storage area.

Rotate stock on a first in, first out

basis as good practice.

Ensure required fire protection is

provided in the storage area.

Ensure emergency contact numbers are displayed

legibly in the storage area.

FREE - SAFETY BOOK - ACHIEVE ZERO : INJURIES, INCIDENTS, ILLNESS

Safe Use of Acetylene Gas

Only authorized employees allowed

working with Acetylene Gas

Before using cylinders ensure that employee

have been properly trained and are competent with the equipment being used.

When moving cylinders from the cylinder storage area to the place of work, ensure that the valve is closed and fitted with a protection cap or valve guard. Use a cylinder trolley. Never shift the cylinders without trolley.

Before commencing work, ensure the

work area is adequately ventilated, clean and that appropriate risk assessments

have been conducted.

Equipment shall be designed

specifically for acetylene (propane or oxygen equipment might not be suitable)

and shall be kept in good working condition and free from oil or grease.

ROAD SAFETY MONTH SAFETY RULES ON THE ROAD

Ensure flashback arrestors and check (non-return)

valves are installed.

Ensure availability of appropriate and

adequate fire extinguishers. It is strongly recommended that dry powder type

fire extinguishers are available close to or in the work area.

Do not use the cylinders in horizontal

position, Acetylene cylinders are designed to be used in the vertical position.

This helps to avoid solvent spitting experienced with some types of porous

material.

Flashback occurs when acetylene flow rate is lower than torch demand. Too high flow causes spitting, flame disturbance and reduces the effectiveness of flashback prevention devices.

If spitting continues the cylinder

should be removed from service, marked or labelled and returned to the

supplier.

Cylinders should always be secured ,

for example by means of retaining straps or chain, pallets or barriers, when in

use. Use with trolley always.

ARC FLASH HAZARDS AND PROPER PRECAUTIONS

Do NOT “crack” open the cylinder valve to blow out dust from the valve outlet as there is a risk of ignition. If necessary, clean the outlet valve with a lint free cloth before connecting the regulator.

When connected, ensure that the

regulator pressure is released and face away from the outlet before slowly opening

the cylinder valve.

Ensure that the equipment is leak

tested and purged of air before use.

Before use, check for gas leaks at

each connection with a suitable leak detection product.

Always treat the torch with care.

Never use the torch as a hammer.

No comments:

Post a Comment